Rapid Prototyping Materials: Are They Compatible With EO Sterilization?

January 29, 2023

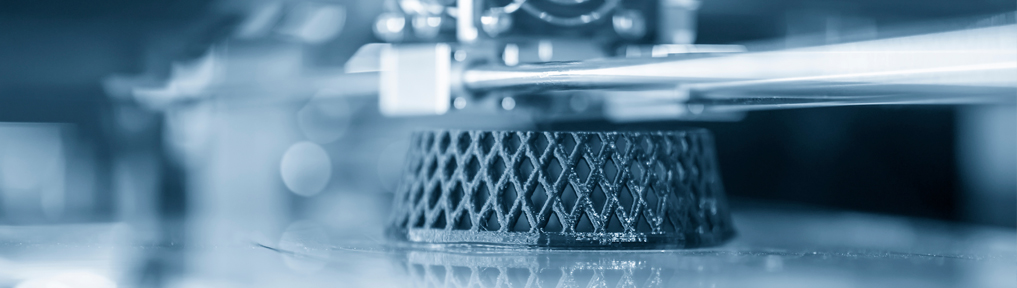

Rapid prototyping (RP) is, yes, we’ll say it, rapidly becoming mainstream in medical device development. Defined as the technique used to quickly fabricate a physical part or assembly, RP generally relies on an additive manufacturing process – commonly known as 3D printing – for manufacture.

Several types of RP exist. While the choice depends on materials, complexity of the part and other factors, the primary types we see among medical device developers are stereolithography and fusion deposition. Stereolithography, the first successful method of 3D printing, is affordable and fast. Fusion deposition, or fused deposition modeling, is a relatively inexpensive, easy-to-use process found in most non-industry 3D printers.

As fantastic as RP is – so much so that some companies are making actual devices (not just prototypes) with it – it bears a number of known disadvantages, ranging from lack of accuracy for some parts to inability to handle certain device features.

Material weakening, sweating

One additional issue we’re encountering with clients is in device sterilization. Even in ethylene oxide (EO) sterilization, the sterilization process with the least impact on materials, we’re finding that material properties are often affected. With EO sterilization occurring at 50-60°C and 60% relative humidity over many hours, part-to-part variability may not be due to the EO itself, but to the associated conditions of heat, humidity and vacuum. Most common effects include weakening, changes to material composition and sweating.

Plus, we’ve noted that developers are not always conducting test sterilization runs before attempting sterilization validation. Without completing this standard practice to determine if the chosen materials are appropriate, companies are getting far down the road in the development process before realizing they need to adjust materials. They end up needing to go back to earlier phases in the process, repeat steps, and end up losing valuable time and money.

How to prevent problems

1. Don’t shortcut proven, standard best practices in new-product development. Using a different manufacturing process – such as RP – doesn’t mean you should eliminate steps in the full development process. They’re there for a good reason.

2. Stay flexible, and be prepared for change. In RP, you may encounter problems and need to make adjustments or go through a few iterations with your device.

3. Work with a manufacturer that specializes in smaller volumes, can diagnose problems swiftly, and make needed changes. Focus on the big-picture goal of getting your device to market as efficiently and quickly as possible.

As we continue to work with more clients using RP, we’ll be able to refine and improve our expertise with materials used, and their compatibility with EO sterilization. We’ll keep you updated. In the meantime, if you have questions about sterilization of your device made with RP, don’t hesitate to let us know.

By Jim Kasic, Founder and Chairman, Boulder iQ