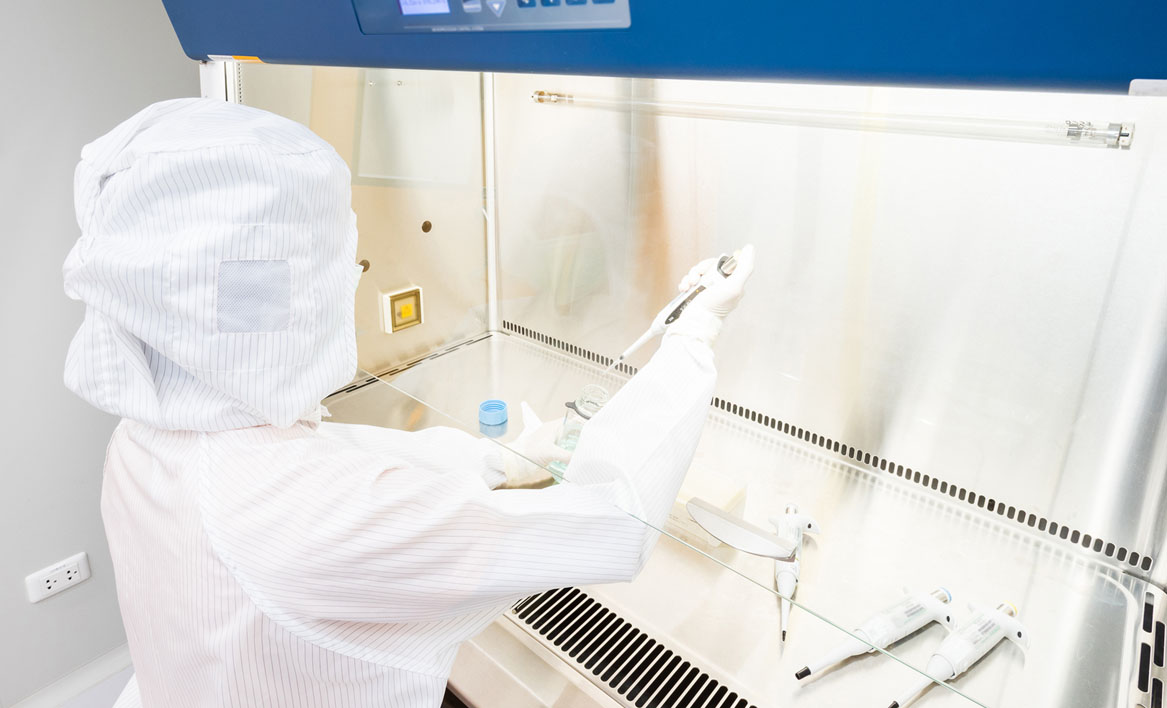

Precision assembly and manufacturing

Boulder iQ specializes in assembly, light manufacturing and packaging in its ISO Class 7-equivalent, controlled environment. Focusing on quality and inspection, processes include adhesive bonding, RF welding, silicone molding and testing (tensile, peel and pressure). Ethylene oxide sterilization complements these services. All products are manufactured in compliance with FDA and CE requirements.

Precision assembly and manufacturing for low-volume, high touch products

![]()

We specialize in assembly, light manufacturing and packaging in our ISO Class 7-equivalent, controlled environment. Focusing on quality and inspection, our processes include adhesive bonding, RF welding, silicone molding and testing (tensile, peel and pressure). Ethylene oxide sterilization complements these services.

In-House Packaging, Labeling, Validation

![]()

Customizable packaging capabilities include tray and pouch sealing within a Class 7-equivalent controlled environment. In-house labeling and secondary packaging assure that each product is customer-ready. Boulder iQ also provides ISO 11607 packaging validation work for terminally sterilized devices, including the development, execution and delivery of protocols and reports.

-

- Distribution/shipping validation

- Shelf life studies

- Accelerated aging tests

- Real-time aging tests

- In-house packaging testing

- Peel strength

- Bubble leak

- Dye penetration

- Visual inspection

We take the quality of our packaging just as seriously as the quality of the device itself. By integrating Boulder iQ’s creative design, engineering performance, and ISO 13485-certification, we deliver a simple, yet elegantly packaged product designed to fit every client’s needs – within the compliance requirements of ISO 13485.